Quality and accuracy

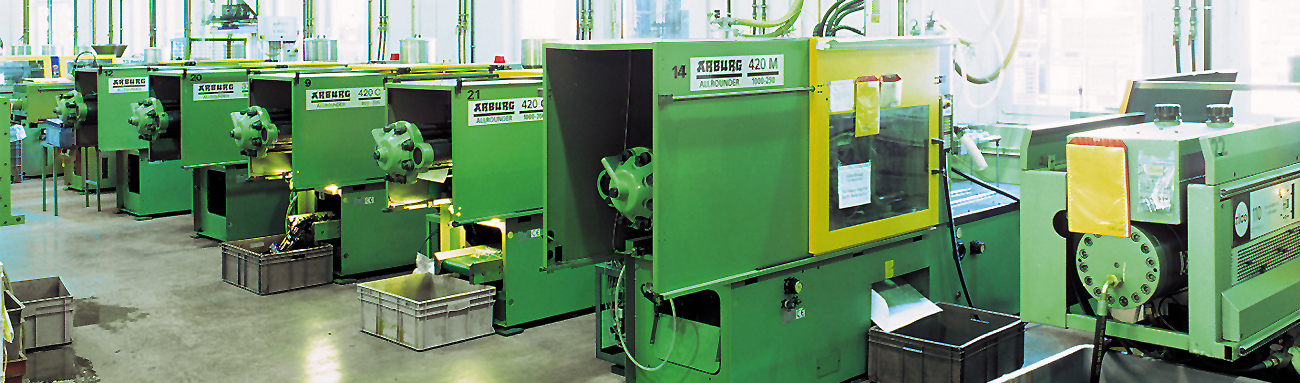

Our stock of machines enables to use machines with locking pressures ranging from 30 t to 1600 t. As a result, we will always be able to fulfil your requirements in the best possible way and guarantee high-grade execution of your order.

Manufacturing processes

- Injection moulding

- 2-component injection moulding

- MuCell

- Hybrid inserts

- Component weights from 0.3 g to 2.5 kg

- Machine sizes with locking pressures from 30 t to 1600 t

Injection-moulded parts

We are a preferred partner both for injection moulding and 2-component injection moulding using a variety of plastic joining techniques. By applying our know-how from all production steps, we can guarantee the production of your products to the highest standards of accuracy and with short response times.

In 2010, we expanded our capacities in the field of 2-component technologies: a further injection moulding machine made by Arburg (model 470C) was commissioned, enabling us to process many different material pairings such as PA/PE, PA6.6 GF/TPE, ABS/TPE and many more.

You can benefit from injection moulded parts made by us due to our excellent flexibility, outstanding quality and adherence to close tolerances.

If you would like to know more about our machine park and production processes or if you have queries about our products and services, please contact us. Use our contact form or send us an email.We look forward to advising you.

Deutsch

Deutsch

English

English